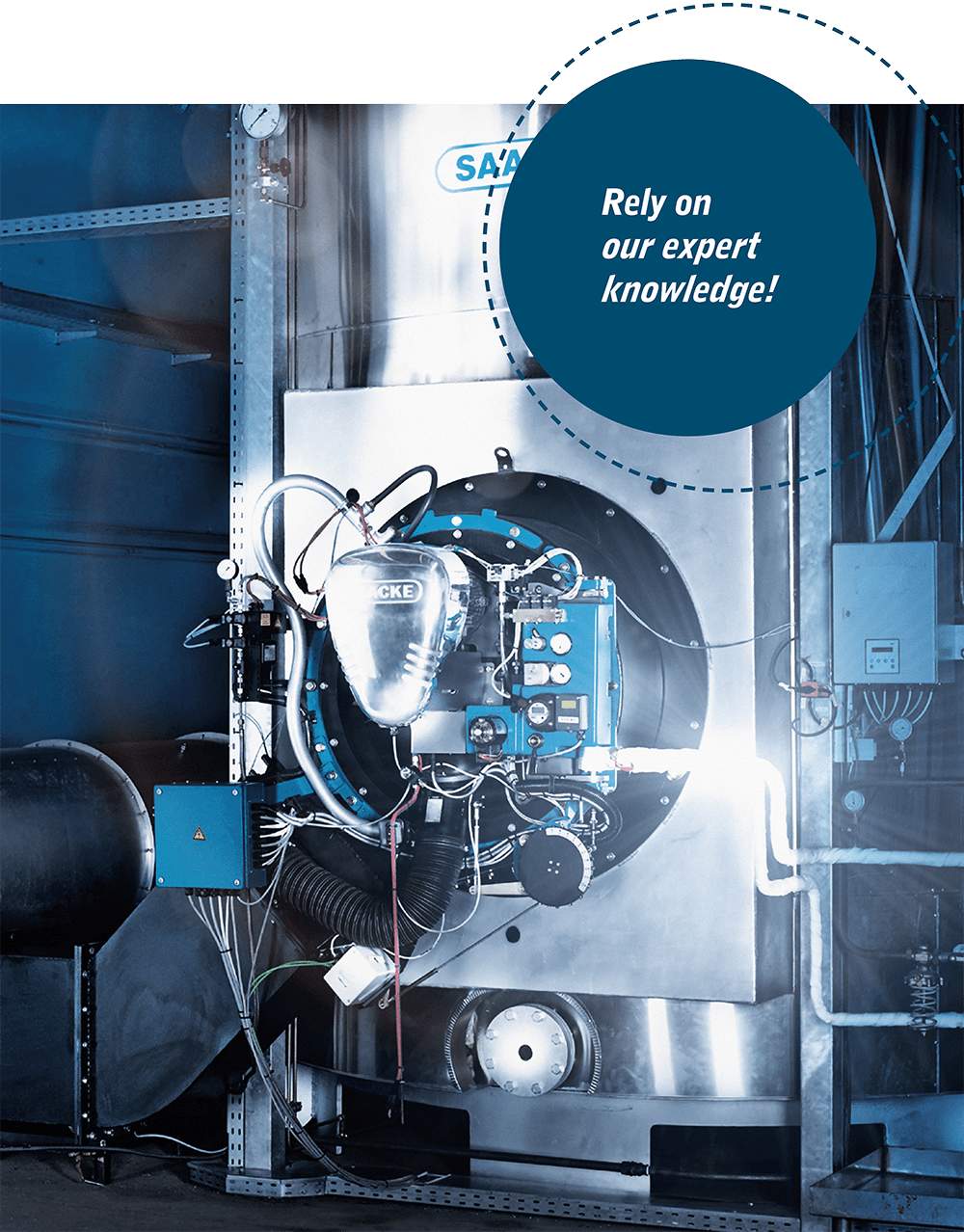

Reliable Steam Generation

SAACKE on board; this means reliable, environmentally friendly and energy-efficient combustion plants for sea-going vessels, offshore plants and LNG tankers.

In order to maintain the high efficiency of any boiler, the most important operation is routine cleaning, in order to remove carbon and particle deposits from inside the tubes.

Boilers are designed to work with a specific flue gas velocity inside the tubes to ensure proper heat transfer to the water/steam side. When the tubes are clogged with soot, the efficiency is significacntly lowered until one day the backpressure is so high that the burner cannot even start.

How to Tell if Cleaning is Needed?

- Visual inspection inside the boiler

- Checking of the exhaust gas temperature (clean if exh. gas is 25oC above figure for a clean boiler)

- Checking the draught loss (clean if backpressure exceeds 150% of clean boiler furnace backpressure)

Keep your Boiler Tubes Clean the Easy Way

The investment will easily be recovered by higher boiler efficiency and less fuel consumption. And less headache for the vessel, managers and owners because a clean boiler will avoid burner trouble from high backpressure, expensive spare parts, loss of EGB efficiency during slow-steaming.