Adiabatix Oy offer a wide variety of thermal management & advanced insulation solutions for all kinds of ships. The company is based in Vaasa, Finland and has been operating since year 2000, developing and manufacturing heat shields for the shipping, offshore, nuclear & power industries.

Using thermal imaging technology, Adiabatix’s experienced staff is able to identify and evaluate problems in the heat insulation of ship engines, exhaust manifolds, turbochargers, exhaust pipes & ducts, report findings and give recommendations to the owners for corrective actions to be undertaken.

What Adiabatix offers :

- Thermal scanning of ship’s engine systems and reporting of hot spots in insulation.

- Fixing hot spots in insulation by supplying and installing either metal heat shields or, insulation mattresses.

- Spray shield covers for pipe connections

On Site Survey and Reporting by ADIABATIX Insulation Specialists

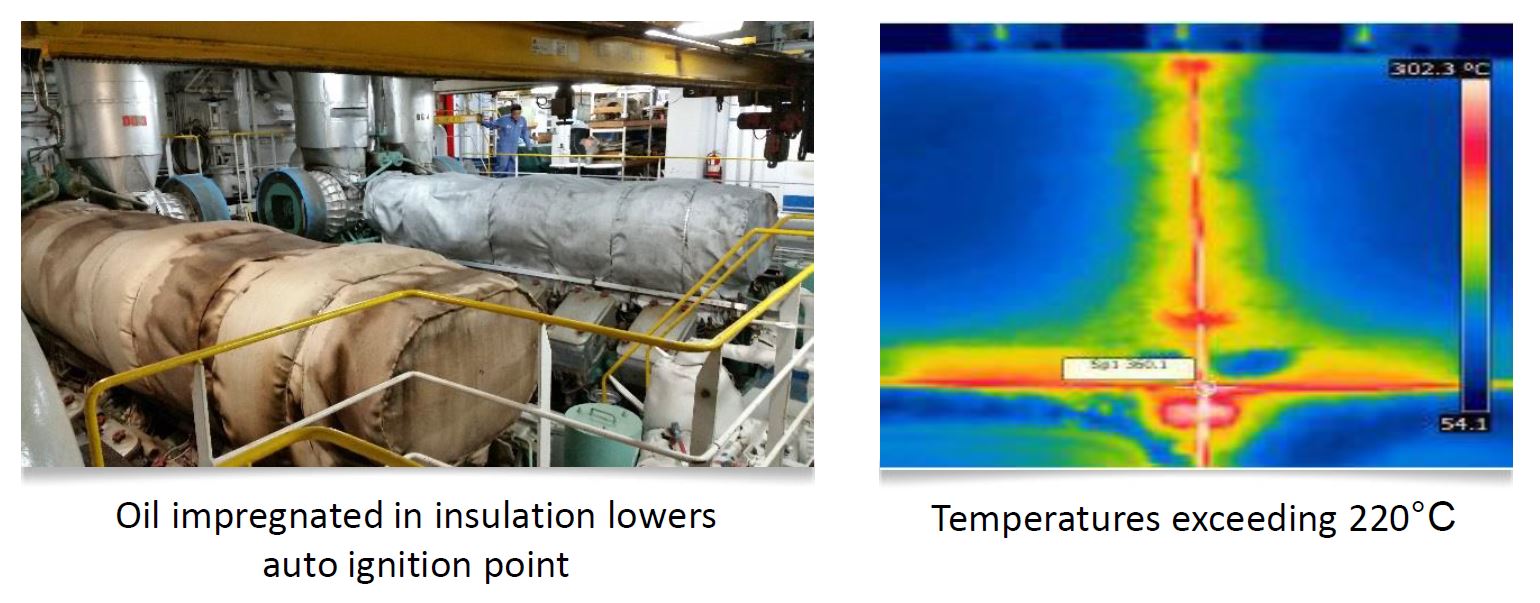

Oil leakage hitting hot spots on engines is the most common cause of engine room fires on board ships.

According to statistics, more than 60% of all engine room fires have been initiated by a hot spot. Most lubrication, hydraulic and fuel oil have an auto ignition point above 250deg C. If a liquid hits a surface hotter than its auto ignition temperature, the liquid may ignite spontaneously.

The relevant rule references can be found in the DNV rules for classification of ships Pt.4 ch1 Sec.3, A507 and SOLAS Ch.II-2, Reg.15.2.10 (implemented July 1998 – not included in SOLAS consolidated edition 1997). DNV surveyors should also apply IS I-B4.3 (2.7, 3.7 checklist) and IS I-C2.3 (2.3).

Thermal imaging technology has become one of the most valuable diagnostic tools for industrial applications. By detecting anomalies and hot spots that are usually invisible to the naked eye using thermal cameras, it enables operators to take corrective actions for avoiding costly system breakdowns or even worse, fire.

Adiabatix can carry out onsite survey – using thermal imaging technology – for identifying areas in the engine room (ship’s engines, exhaust manifolds & turbochargers) which constitute an immediate hazard for the ship and assist customers to spot the gaps in their existing insulation systems, as well as to undertake restoration actions based on Adiabatix’s findings & recommendations, in order meet the regulations like SOLAS and ATEX.

Adiabatix can fix and renew faulty insulation systems quickly and effectively by deploying worldwide a 2-man specialized insulation team onboard a ship with all necessary tools and certified insulation materials. Insulation works results are verified by ADIABATIX’s technicians, with thermal imaging camera and final reporting.

Besides the final report on the insulation works results, the client also receives from ADIABATIX the following documentation in electronic format:

- Mattresses Parts Manual – including drawings – for easy reordering of damaged mattresses.

- Instructions manual for the proper use of installed insulation mattresses.

Why Choose ADIABATIX?

1. Vast know-how of marine engine room environment through many years of experience from various engine types and makers.

2. Customer enjoys full service from us:

- Finding and reporting of problems by thermal imaging technology.

- Suggestions for appropriate and cost-effective correction measures (we are not “over-selling” anything to customer)

- Efficient fixing of problems by skillful professionals using the right tools (our own portable workshop with sewing machine etc.). Tailor made insulation manufactured on site resulting to best possible insulation for each case.

- Final verification by thermal imaging and reporting of results ( = work is not finished until results are approved in collaboration with ship staff)

3. Comprehensive references from well-established clientele.

Protecting Engine' Hot Spots

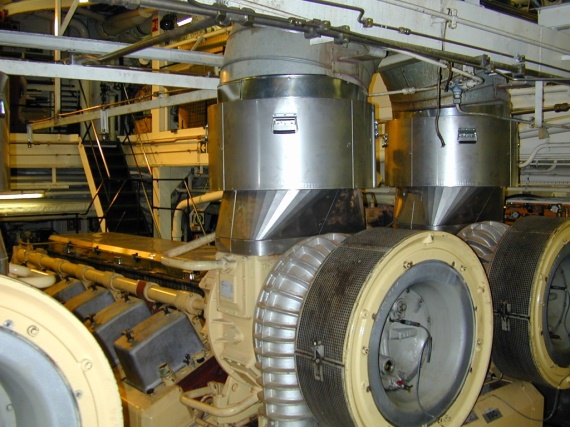

Adiabatix are able to design and manufacture completely new insulation covers for exhaust pipes or tailor made insulation mattresses.

|

|

|

|

||

|

Insulation covers for exhaust bellows |

||||

|

||||

| Special insulation mattress construction | Insulation covers for engines | Insulation covers for engine exhaust pipe |

Adi-Fbox Spray Shields for Pipe Connections

Leakages through valves, flanges and other piping connections are the most common problems that cause serious risk of fire and other accidents in marine, offshore and in other industrial plants. That’s why ADIABATIX designed Adi-Fbox spray shields to protect personnel and equipment.

What are the benefits of Adi-Fbox?

- Solid construction of Adi-Fbox makes it a longer-lasting and re-usable spray shield solution.

- Adi-Fboxes are easy to install and remove without any tools

- Adi-Fbox stands against vibrations and impacts.

- Adi-Fbox prevents liquids, like oil, to spray on hot surfaces.

- Adi-Fbox fulfils the regulations. (SOLAS*, ATEX**)

- Adi-Fbox is available for all DIN, ANSI and PN flange sizes.

- Adi-Fbox can also be used as an insulation cover if needed.

|

|

|||

| Spay shield model 1 | Spray shield model 2 |

Watch the Video

ADIABATIX Reference Clients

|

• Wärtsilä (marine-power-offshore) |

• Fortum | • Wilhelmsen Shipping |

| • Caterpillar/MaK(marine) | • Silja Line | • Royal Caribbean |

| • Forsmark Kraftgrupp (Nuclear) | • RCCL | • Statoil |

| • UPM | • Viking Line | • PGS |

| • Columbia Cruise Services | • Carnival Cruise Lines | • PetroBras |

| • Andritz | • Celestyal Cruises | • Transocean |

Click here to visit Adiabatix Website.