SAACKE steam pressure atomizer DDZ-M: Unrivalled efficiency thanks to 10% less fuel consumption and CO emissions below 20 mg/m³

Specially developed for maritime shipping and FPSO units.

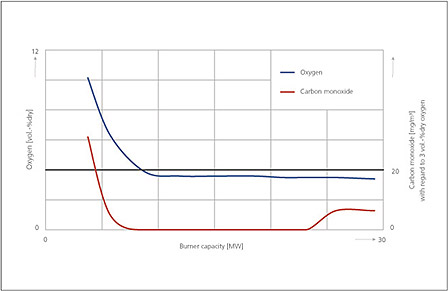

The new DDZ-M involves a special nozzle system with targeted air supply that expands the control range of the burner up to 1:15 and thus reduces CO emissions to less than 20 mg/m³ at the rated capacity. This burner was specially developed for maritime shipping and is fundamentally suitable for use on ships with high heat requirements and in connection with FPSO units.

The heart of this new development is a special nozzle system that enables internal fuel grading and is based on the principle of steam pressure atomization. By means of pressure, steam is fed to the nozzle shaft and at the same time the liquid fuel is inserted in the nozzle via an annular gap. The mix of steam and oil is then pressed into the firing chamber via the nozzle head and very finely atomized to optimize the combustion process.

Ideal distribution of the oil mist in the combustion chamber is extremely important to achieve optimum combustion. If the oil is atomized too finely, it burns too quickly, thus leading to increased formation of nitrogen oxides. However, even too slow combustion due to excessively coarse atomization is disadvantageous because residues are left over in this case. At the same time the temperature should be kept as low as possible in order to reduce thermal formation of NOx. That is why the system is designed such that the reaction in the combustion chamber can be controlled via targeted supply of both the combustion air and the steam-fuel mix. Only in this way is it possible to reduce CO emissions to below 20 mg/m³.

Ten percent less consumption in lower load range

In addition, the controlled air supply enables expansion of the control range. The burner can be brought down to low-load mode. Given a plant capacity from 20 MW and up, the control range is around 1:15 and even at a lower capacity around 1:10. Without this high control range the system would have to be switched on or off about every 15 minutes and would consume measurably more fuel. Furthermore, venting is necessary every time the burner is switched off, resulting in loss of energy and heat. Starting up the system consumes additional energy and takes a certain amount of time until the required boiler pressure is reached. The low-load mode, by contrast, prevents downtime and also improves plant efficiency.

In addition, the controlled air supply enables expansion of the control range. The burner can be brought down to low-load mode. Given a plant capacity from 20 MW and up, the control range is around 1:15 and even at a lower capacity around 1:10. Without this high control range the system would have to be switched on or off about every 15 minutes and would consume measurably more fuel. Furthermore, venting is necessary every time the burner is switched off, resulting in loss of energy and heat. Starting up the system consumes additional energy and takes a certain amount of time until the required boiler pressure is reached. The low-load mode, by contrast, prevents downtime and also improves plant efficiency.

The DDZ-M burner can process both light and heavy fuel oil at a capacity of 8.5 to 37 MW. SAACKE additionally plans to develop and commence production of a dual fuel burner of this series for oil and gas operation on ships. This burner enables changeover from oil to gas operation on entry into port so as to further reduce pollutant emissions and handle local emission regulations.